|

|

|

|

|

|

TECHNOL - POLYIMIDE FILMS

HOME >> PRODUCTS >> TECHNOL >> POLYIMIDE FILMS

Technol's High Quality Polymide Films comes in various dimensions to cater to various application. Highly resistible to extreme temperatures to provide functionality during application.

Download

Technical Specifications Comparison Chart PDF (Not Available)

* Click Product Code to view Technical Data Sheet

| Type | Description | Application | ||||

| PA 90 | Excellent combination of mechanical, physical, chemical and electrical properties; Withstand a wide range of temperature ranging from -269°C (-452°F ) to 400°C (752°F). Self-extinguishing and non-melting | Flex printed circuits, motor slot liners, magnetic wire insulation, dielectric layers for IC packaging, TABs (Tape Automated Bonding), protection layer in electronics, and backing material for polyimide tape, etc | ||||

| PD 90 | Beside all the properties PA 90 has, PD 90 and PE 90 are extremely good in dimensional stability | FCCL, coverlay, voice coils, flexible circuits | ||||

| PE 90 | ||||||

| PF 90 | PA 90 Polyimide film laminated with teflon | Magnet wire insulation, release film | ||||

| 1. PA 90, PD 90, PE 90, PF 90 PI Film Grade | ||||||

| Product No. | Thickness (mils) | g/m² Density | ||||

| PA 90/#50 | 0.5 | 18+/- 2 | ||||

| PA 90/#100, PD 90/#100, PE90/#100 | 1 | 35 +/- 5 | ||||

| PA 90/#200, PD 90/#200, PE90/#200, PF 90 #200/919 | 2 | 71.5+/-5 | ||||

| PA 90/#300, PD 90/#300, PE 90/#300 | 3 | 106+/-7 | ||||

| PA 90/#400 | 4 | 142+/-10 | ||||

| PA 90/#500 | 5 | 179+/- 13 | ||||

| PA 90/#600 | 0 | 213+/-15 | ||||

| PA 90/#700 | 7 | 250+/-18 | ||||

| PA 90/#800 | 8 | 285+/-20 | ||||

| PA 90/#900 | 9 | 322+/-22 | ||||

| PA 90/#1000 | 10 | 357+/-25 | ||||

| 2. Mechanical and Electrical Properties | ||||||

| Properties | Units | Typical Value | Testing Condition | Test Method | ||

| (%) | (%) | (%) | ||||

| Tensile Strength | MD | Mpa | 180 | 23°C | ASTM D-882 | |

| TD | 160 | |||||

| Elongation | MD | % | 90 | 23°C | ASTM D-882 | |

| TD | 87 | |||||

| (PA 90, PF 90) Shrinkage | % | 0.2 | 200°C, 2hr | IPC-TM-650 2.2.4A | ||

| Dielectric Strength | KV/mm | 200 | 60Hz, 23°C | ASTM D-149 | ||

| Volume Resistibility | Ω - cm | 1.1 x 10 13 | 500V, 23°C5 | ASTM D-257 | ||

| Dissipation Factor | - | 0.009 | 1kHz, 23°C | ASTM D-150 | ||

| Dielectric Constant | - | 3.5 | 1kHz, 23°C | ASTM D-150 | ||

| Surface Resistibility | Ω | 1.2 x 10 14 | 500V, 23°C | ASTM D-257 | ||

| Properties of PD 90, PE 90 Thermal PI Film | ||||||

| Properties | Units | Typical

Value PD 90 PE90 |

Testing Condition | Test Method | ||

| Shrinkage | % | 0.07 0.05 | 200°C, 2hr | IPC-TM-650 2.2.4A | ||

| Coefficient of Thermal Expansion | ppm/°C | 12 9 | 30-100°C | TMA Method | ||

| 20 16 | 100-200°C | |||||

| 27 19 | 200-300°C | |||||

| 25 17 | 30-300°C | |||||

| Properties PF 90 PTFE / PI Film | ||||||

| Properties | Units | Typical Value | ||||

| PF 90 #120/616B | PF 90 #150/019 | PF 90 #200/919 | ||||

| Thickness | mil | 1.2 | 1.5 | 2 | ||

| Tensile Strength | Mpa | 150 | 160 | 180 | ||

| Elongation | % | 83 | 87 | 90 | ||

| Heat Seal Strength | Film to film | kg/25mm | 1.4 | 1.4 | 1.6 | |

| Film to copper | 1.3 | 1.4 | 1.5 | |||

| Breakdown Voltage | KV/mm | 203 | 212 | 224 | ||

|

||||||

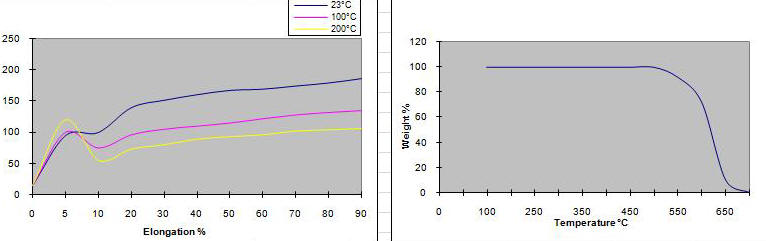

| Tensile Strength -Strain Curve (Technol PA 90 Film, 1mil thickness) | Thermal Degradation (Technol PA 90, PF90 film, 1mil thickness heat rate: 10°C/min, in the air atmosphere) | |||||

| *Polyimide Film Suppliers Cross Reference | ||||||

| Technol ® | Kapton ® Toray DuPont | Kapton ® E I DuPont | Apical ® Allied-Apical | |||

| PA 90 | HN | HN | AV | |||

| PD 90, PE 90 | EN | VN | NP | |||

| PF 90 | - | FN | AF | |||

.